AGRO_GAZELEC - Energy from agricultural industries waste through local appropriation and deployment of gas generators

The development of a viable solution for the electrical recovery of agricultural and agro-industrial waste, for powers of 100 kWe to 2 MWe with a strong impact on local economies, the local and global environment and climate change, such is the objective of the Agro_Gazelec program

Examples of waste that can be recovered within the Agro_Gazelec program

Key informations

Context and challenges

In West Africa, sustainable energy recovery from biomass has significant development potential. Moving up the agribusiness value chain is now a major economic challenge, both to maximize national added value and in terms of job creation. One of the most dynamic sectors is the cashew nut priority for the two targeted countries (Côte d'Ivoire, the world's leading producer) and Benin. Local processing is still weak but increases every year and allows job creation. Its competitiveness is an important issue in a West African context where, in 2022, more than 85% of the raw nut is still exported to Vietnam and India for processing.

The recovery of agro-industrial waste is an important environmental issue. Indeed, depending on their type, waste can present significant risks of soil, water and air pollution (linked to combustion or methanation in the open air) as well as risks of fire. They also represent an opportunity with the objective of reducing the cost of processing products through the production of electricity which contributes to the energy efficiency of the unit which becomes a self-producer in substitution for consumption on the electrical network. This clean and local production is also valuable for electricity companies to improve the quality and access to services.

Descriptif

This project concerns the recovery of solid waste and on gasifiers suitable technology with a unit power of 90 to 220 kWe which can reach 2 MW in series. The innovative aspect is the use of engines powered 100 by synthetic gas from waste recovery (instead of diesel hybrids). These powers correspond to the sizes of existing and planned agro-industrial processing units in West Africa, and make it possible to overcome the question of the availability of large quantities of biomass, a major risk factor for higher power units. (boilers of 5 MW or more).

The FISP of the FFEM supported a first series of installations in Cambodia, which made it possible to mobilize a group of SMEs which locally manufacture the gasification unit, gasifier, gas cleaning system, gas engines, biochar briquetting unit. These units have been developed since 2014 with the introduction of multi-faceted innovations and transformations: technological, institutional, financial, organization of operations. It is a question of reproducing towards Africa the transfer of technology carried out gradually in Cambodia by providing the means for local appropriation to sustain its operation.

SraEm plant in Cambodia (800 kW net)

Objective

The objective of the program is to develop a viable solution for the recovery of agricultural and agro-industrial waste for powers of 100 kWe to 2 MWe with a strong impact on local economies, employment, the local environment and the climate change, through a transfer of manufacturing and operating know-how already operational in Cambodia. An important training-action component will make it possible to manufacture the first units, and to install and operate the first installations in Africa. The innovation will also relate to institutional arrangements in a context where, while self-production and independent production are authorized in West Africa, the regulatory frameworks remain cumbersome and require incentives that are more conducive to renewable energies, financing remains a real challenge for complex and small-scale projects mobilization of impact funds and guarantee instruments is to emerge.

Program components

1. Capitalization on the experience in Cambodia

- Manufacture of gasifier and filters + water and ash treatment; Adaptation of 100% gas engines;

- Operation and maintenance of a 100% gas-powered plant;

- Training through staff exchanges Cambodia – Benin / Ivory Coast.

2. Structuring of the industrial sector

- Local manufacturing to achieve acceptable investment costs with local availability of spare parts;

- Structuring and operator support for the design, monitoring of works and commissioning (EPC);

- Structuring and operator support for the operation and maintenance of gas power plants.

3. Achievements on the ground

- Identification of about fifteen agro-industries; feasibility studies, constitution of a portfolio of project opportunities;

- Selection of 2 manufacturers for the production of pilots; Design and assembly of projects;

- Implementation and training then support for operation; launch of a second operation and establishment of a portfolio of projects.

4. Implementation of training and follow-up / scientific capitalization

- Training through physical exchanges on site in Cambodia and vice versa;

- Training programs with technical universities;

- Monitoring and follow-up activity / scientific capitalization.

5. Replication and sustainability

- Based on the first results, support for dissemination;

- Actions to protect the local environment in the achievements, CSR, local energy recovery;

- Establishment of a gasifier production chain with its business plan and project pipeline;

- Dissemination in the sub-region: website, discussion workshops; publications.

Technology developed

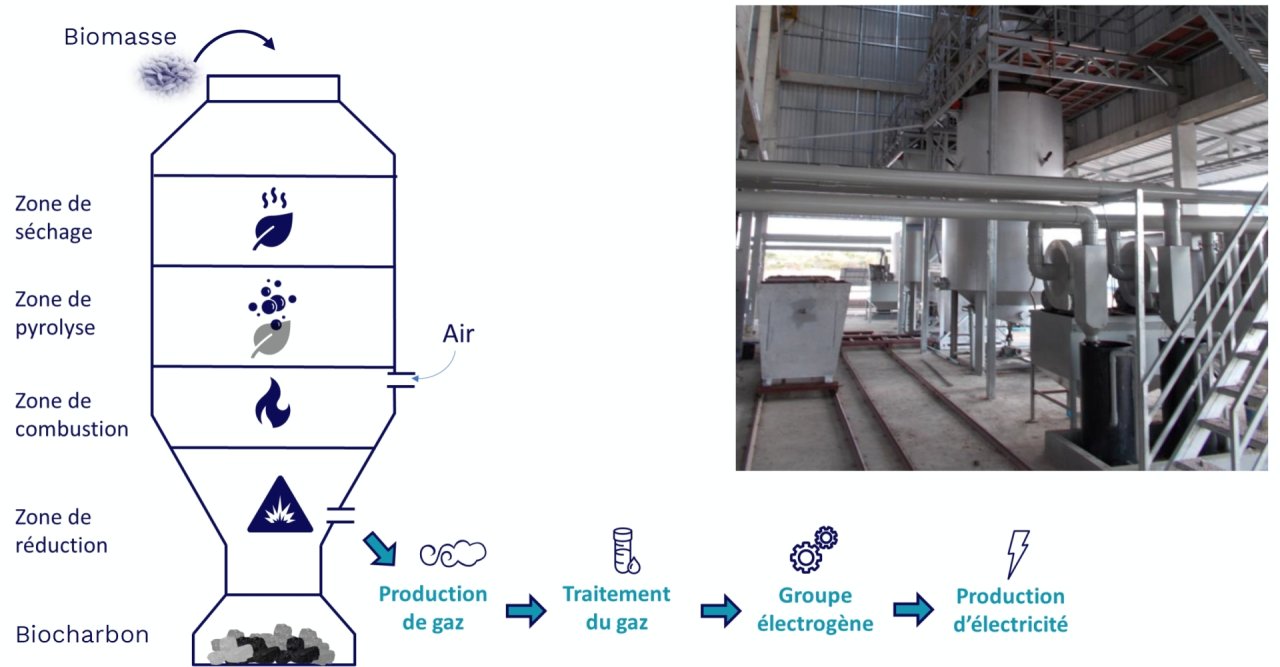

The technology used is gasification. This is a thermochemical conversion of solid and dry biomass into synthesis gas, which, once cooled and cleaned, is used to supply a generator

Gasifiers deployed in this project are fixed-bed co-current gasifiers Biomass enters the top of the gasifier, gas and biochar are extracted from the bottom.

Gasification block diagram

Related people

Magloire Sacla Aïde

Design & Mechanical Engineer, specialised in "Energy and industrial technician in mechanical production" from the Ecole Polytechnique of Abomey Calavi (EPAC) in Benin, he brings his expertise in renewable energy including biomass energy recovery and industrial process

See more

Hervé Abbo

Holder of a diploma in Energy Engineering and a master's degree in International Relations, he worked on improved stoves on behalf of organizations such as the Ministry of Energy and GIZ in Benin. Before joining the team, he worked as a Green Energy Project Manager (Recovery of biodegradable household waste into biofuels) for a Benin-French NGO

Cédric Rabany

Holder of a Master of Science, "Agricultural Engineer and territories development" from the Institut Supérieur d’Agriculture (ISARA Lyon), he brings his expertise in agro-food/agricultural sectors' analysis and development, strengthening of supplychain actors (producers, private/public actors, agro-food industries...), socio-economic analysis of agricultural chains and his great knowledge of companies in these markets

See moreEtienne Perrier

Having graduated from the Engineering School INSA of Lyon as an Engineer in Energy & Environment, option "Thermal systems engineering", Section "Top-level sport", he brings his expertise in renewable thermal systems implementation and analysis, in the food processing industry (shea and cashew), waste recycling and training of local experts

See moreH2CI - Feasibility study for the instal…