AGROVALOR - Energy valorization of agro-industrial waste in Côte d'Ivoire

Partners

Main goals

Disseminate energy recovery equipment for agro-industrial waste in Ivoiry Coast, adapted to the local context to promote agro-industrial waste from the cashew, cassava and shea sectors, particularly in the cities of Bouaké and Korhogo, by ensuring a transfer of skills for replication of these technologies in Côte d'Ivoire.

Specific objectives

- Design and commercialize appropriate technologies for energy recovery of cashew nuts and cassava and shea processing wastes

- Strengthen local skills by training young technicians, structuring equipment operators and the appropriation of results by a public institution Energy recovery

Beneficiaries

- Direct beneficiaries: companies, cooperatives or productive groups (associations or GIEs) active in the processing of cashew, shea or cassava

- Indirect beneficiaries: the employees of these structures, mainly women whose revenues will be consolidated

Results

** R1. ** At least 8 cashew processors are equipped with a pyrolysis furnace for shell enhancement

** R2. ** At least 30 groups of women producing attiéké and 6 groups of women who process shea have acquired energy equipment (improved biodigester and / or oven)

** R3. ** A training program for young technicians is developed with 2 training modules

** R4. ** 3 OEM operators are created or strengthened to respond to other requests

Activities

** A1. ** Realization of 12 techno-economic design studies in cashew processing units

** A2. ** Installation of 8 ovens and training of staff of each beneficiary

** A3. ** Valorization of shell biochar

** A4. ** Phase 1: Design and installation of biodigesters and kilns in 5 attiéké processing groups and 1 shea processing group

** A5. ** Phase 2: installation of improved biodigesters and fireplaces in 25 attiéké groups and installation of equipment within 5 shea groupings

** A6. ** Economic and Environmental Assessment and setting up of a financing mechanism adapted to women's groups

** A7. ** Sensitization and capacity building of women's groups

** A8. ** Development of vocational training programs and selection of two training centers

** A9. ** Training of 10 artisans in metallurgy and 10 masonry craftsmen for the manufacture of ovens

** A10. ** Opportunity study of replication of vocational training

** A11. ** Evaluation of existing equipment suppliers in the fireplaces and ovens sector

** A12. ** Support for the creation or strengthening of 3 operators able to design, market, manufacture and install broadcast equipment

Related documents

Monitoring report of the treatment system by settling and filtration of cassava juice

Final external evaluation report of the Agrovalor project in Côte d'Ivoire

Catalog of biomass recovery technologies from agro-industrial waste

Performance analysis and improvement of the technologies developed by Nitidæ for the production of bioenergy within the framework of the Ag…

Study of the non-renewability of wood (NRW) and measurement of improved stoves uses effects

Valorization of shea effluents, study of by-products and performance monitoring of shea biodigesters in Korhogo

Final evaluation report of the AGROVALOR RCI project

Treatment of effluents from the production of shea butter

Study report on opportunities to replicate professional training for equipment dedicated to processors of agricultural products

Flow of products, waste and combustibles at Tchêregnimin and impacts of Agrovalor equipment

Valuation report of the liquid digestate from the biodigestion of cassava juice

Report on the study to optimize the methanogenic potential of effluents from cassava pulp

Energy engineer internship report - valorization of cashew shell charcoal from pyrolysis ovens

Report of the characterization of vertical and horizontal briquetting presses

Summary of the Attiéké sector study in Côte d'Ivoire production, processing, market

Decision support report for the definition of the study on the reduction of smoke within the cashew industries

Report on the monitoring of training in simplified accounting for the benefit of managers of attiéké production groups in Bouaké

Note - Agrovalor Project: biomass energy producers utilizing agro-industrial waste

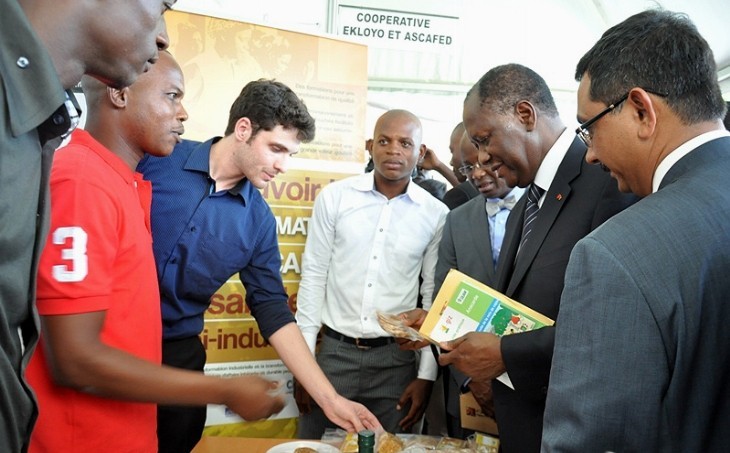

Presentation of the Agrovalor project Energy valorisation of agro-industrial waste in Ivory Coast Bouaké & Korhogo

Characterisation and thermochemical processing of cashew nuts for their energy recovery in traditional processing techniques

Related people

Jules-Dorgeles Gomeu

Holder of an engineering degree in management of mining, oil and energy activities, he brings his expertise in the coordination, implementation and monitoring of project activities implemented by Nitidae in the shea processing sectors, cassava and cashew nuts, with particular expertise in supporting cooperatives and agri-food industrial units. With significant experience in managing projects on the processing of cassava, shea and cashew nuts financed by national and international institutions such as FIRCA, USAID and AFD, the Rhône-Alpes Region, he enjoys an ability to effectively coordinate teams, manage administrative and financial aspects, as well as cultivate fruitful relationships with partners and stakeholders. His solid academic background in engineering and project management complements his profile, allowing him to approach complex challenges with a holistic and strategic approach.

See moreJulia Artigas Sancho

Process engineer and holder of a European MsC in Renewable energies, she works on energy-related issues in African industry, since 2016. Process optimization and agri-waste-to-energy systems are her main expertise areas: appropriate technologies, training on operation and maintenance, biofuels…

See moreBenjamin Garnier

Agricultural Engineer, specialised in "quality of the environment and resources management", from the French National School of Agricultural Science and Engineering of Toulouse (INP ENSAT). He brings his expertise in feasibility studies for investment funds, agricultural markets studies and analysis of value chains

See more

Dohomin Alain Yéo

Recruited for the Agrovalor project, he then joined the Shea Gets Greener team until 2023. He is now based in Dabakala where he works as a courier driver for the PapBio2 project.

Abel Dègnimon Sogbegnon

Holder of a Master's degree in energy and electrical engineering (2IE, Ouagadougou) and a Master's degree in Science and technology with a physics option (UAC, Benin). Abel joined the Nitidae team in 2020 on the Agrovalor project and subsequently worked on the Shea gets greener project. He has expertise in agri-food production processes, drying technologies and energy recovery from waste (biomass) thermally (Gasification/Pyrolysis) in West Africa. It works in close partnership with local workshops and entrepreneurs in a skills transfer approach.

Magloire Sacla Aïde

Design & Mechanical Engineer, specialised in "Energy and industrial technician in mechanical production" from the Ecole Polytechnique of Abomey Calavi (EPAC) in Benin, he brings his expertise in renewable energy including biomass energy recovery and industrial process

See more

Fatima Anne Andrée Loum

Holder of a Master's degree in Audit and Management Control from the Private University Faculties of Abidjan (FUPA), she joined the team in October 2021 as an accounting assistant for the Agrovalor project before joining the Shea Gets Greener team until in 2023. Based in Abidjan, she now serves as Project Accounting Administrator on the PSECO project.

ELECTRICI - Recycling of cashew waste i…