Agrovalor Platform

Nitidæ develops bioenergy projects for populations with little access to energy and for economic actors wishing to increase the added value linked to the local processing of raw products. In addition to the production of biogas (rural and peri-urban) and the improvement of techniques for the use of wood-energy (charcoal sector), Nitidæ emphasizes "agro-energy recovery" of waste resulting from the transformation agro-industrial. The challenge of waste recovery: in waste we trust!

The complete catalog of agrovalor technologies is available here

The challenge of agro-industrial waste repurposing in developing countries

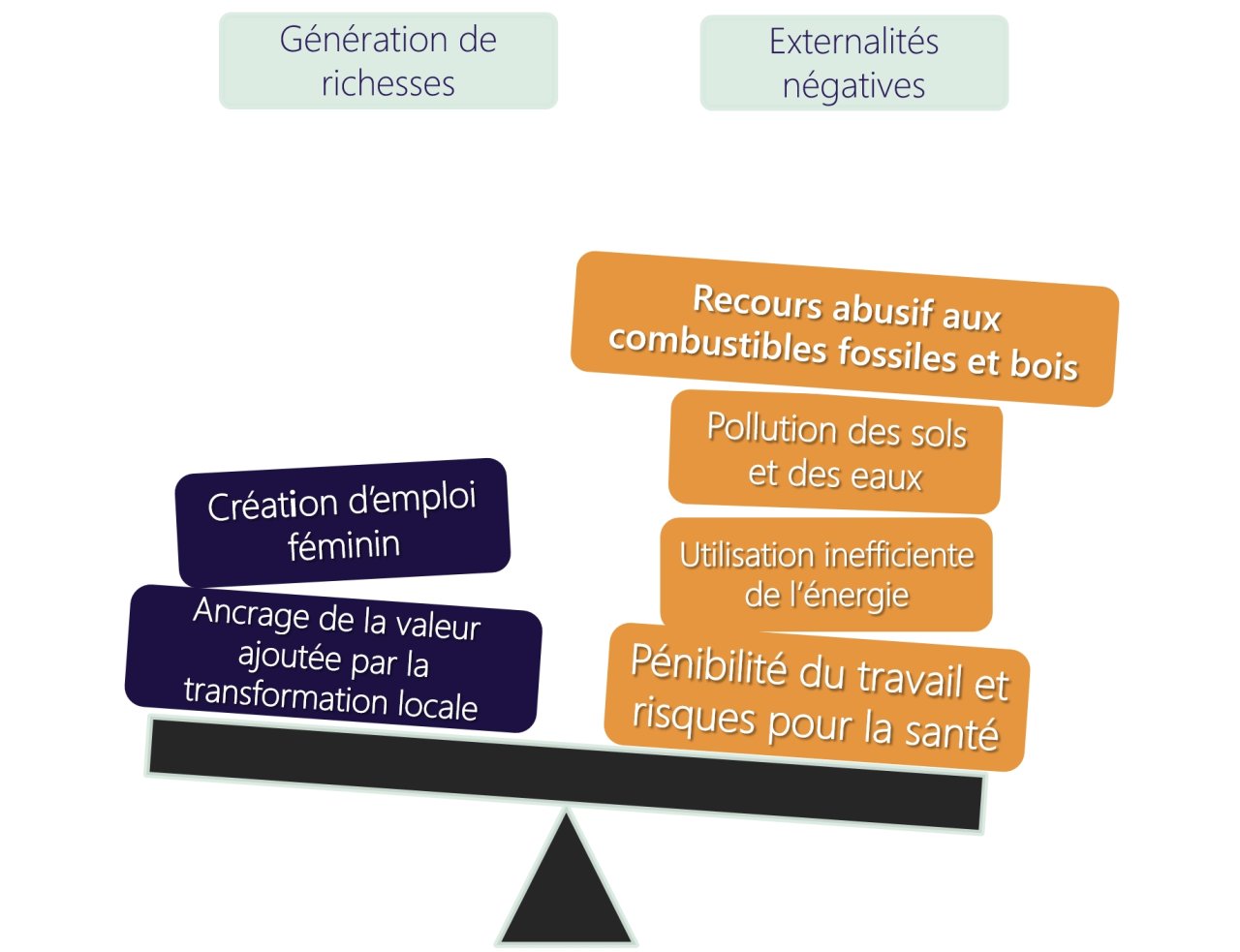

Committed to numerous actors from the agro-industrial sector, Nitidæ noticed that the development of agro-food processing factories in developing countries can have serious consequences over their environment. On one hand, the production of energy necessary for the transformation processes often leads to intensive consumption of firewood, impacting the forest cover. Other times, fossil fuels provide the necessary energy. On the other hand, waste generated from this process is released in natural environment; in which it sometimes degrade very slowly, polluting soil and groundwater. This is how these industries, containing enormous potential for generating wealth, cause harm that in some cases exceeds the benefits that can be generated in the first place.

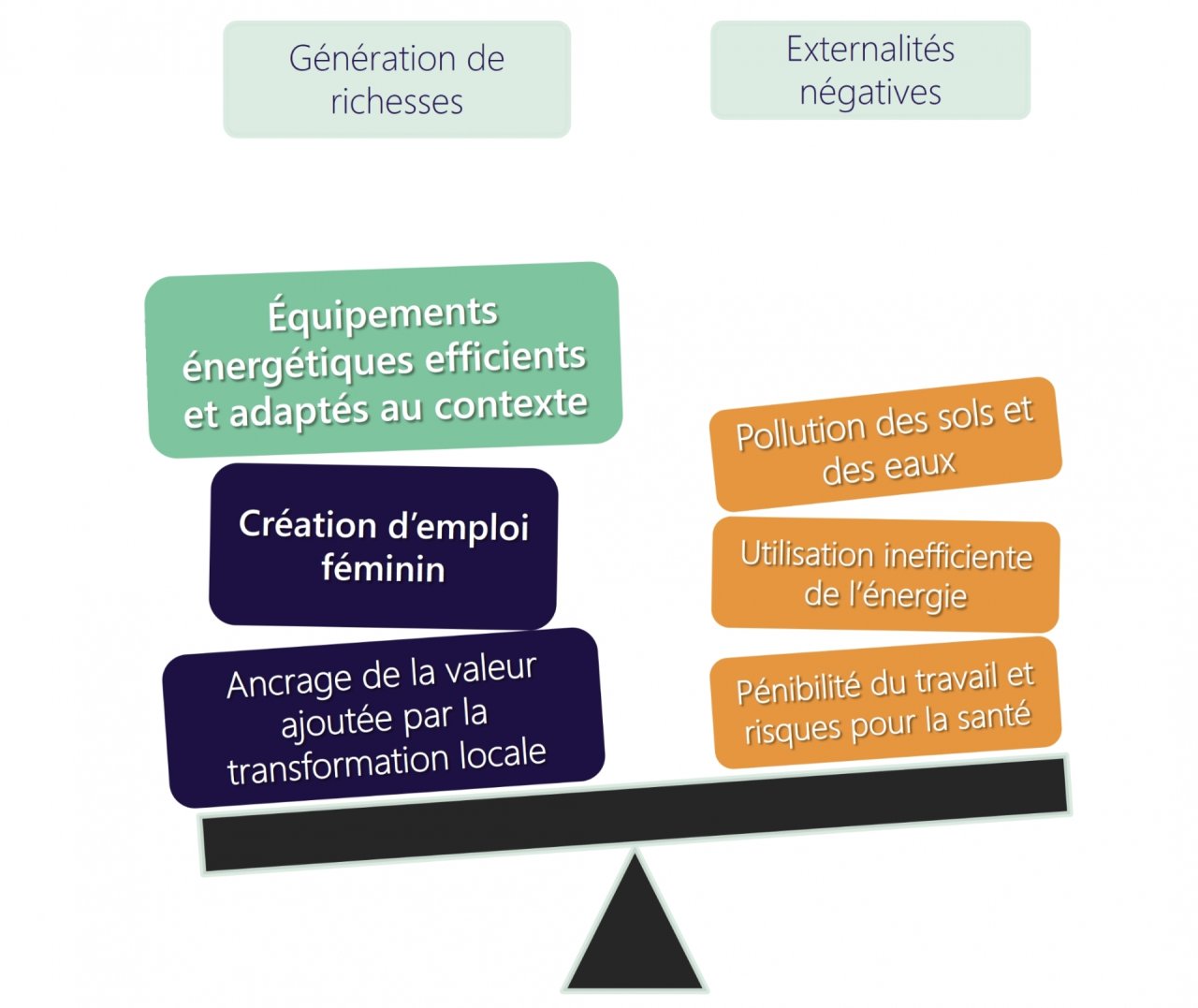

In order to address those issues more effectively, Nitidæ developed an innovative technology allowing the production of the necessary energy for processing factories by reusing unvalued, polluting and bulky waste: not only the amount of waste released into the environment is reduced, but these same waste produce a clean and profitable energy that reduce consumption of firewood...!

Efficient energy equipment adapted to the context

Since its inception, Nitidæ has partnered with specialists to meet the agrovalor challenge. The work in coordination with our partners in the world of research, local equipment manufacturers, and the industrialists who are the target of these technologies, has made it possible to design and distribute a wide range of equipment, locally manufactured and adapted to the realities on the ground, among which:

- H2CP Pyrolysis Oven (link to the dedicated page)

- Improved double pot oven (link brochure)

- Improved roaster (link brochure)

- Motorized biomass briquetter (link brochure)

- Liquid waste biodigester (link brochure)

- Shea cake settling tank (link brochure)

Download the catalog of biomass recovery technologies from agro-industrial waste here

Our Agrovalor platform offers a set of equipment that goes beyond the framework of the H2CP furnace and completes it: installation of suitable boilers and equipment requiring heat (autoclaves, dryers, etc.), effluent management systems, drying equipment solar energy, design of briquette presses (biochar), improved stoves and ovens adapted to a specific use, etc. Finally, the agro-recovery of waste may not only be energy: bio-waste may be suitable for composting, or its recycling as plant fertiliser, animal feed or work material. Agrovalor is the circular economy of agricultural waste!

Our know-how

The Agrovalor approach is based on a pragmatic vision of the needs and objectives of local industrial players, with solutions adapted to each, after a complete diagnosis of their production process and their objectives. This offer can range from a simple diagnosis to the design and implementation of the proposed solutions:

(i) needs analysis (ii) feasibility study, estimation of economic and environmental benefits (iii) design and manufacture of equipment, together with local equipment manufacturers (iv) on-site installation (v) training of staff in its use and maintenance, etc. (vi) training of equipment manufacturers, capacity building of local bioenergy entrepreneurs.

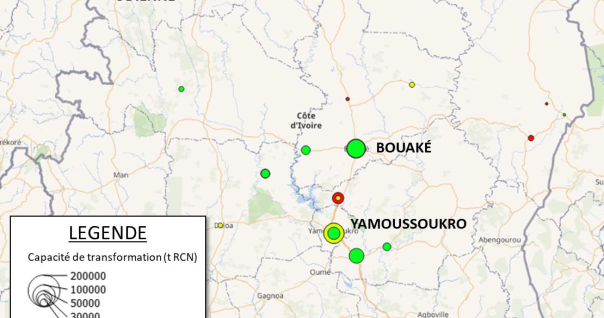

The Agrovalor RCI project is a showcase of Nitidæ's work for the recovery of agro-industrial waste.

The Agrovalor platform has its own site, the biofuel platform, located in Bobo-Dioulasso in Burkina Faso. These facilities have the necessary equipment to carry out technical studies for the recovery of various waste: combustion, pyrolysis, carbonization, briquetting… Contact us and tell us about your bio-waste recovery project!

In practical terms, what is the impact of agro-industrial waste repurposing ?

Health and environmental benefits

- Reduction of deforestation and GHG: reduction of carbon emissions related to intensive timber consumption and protection of forest cover.

- Waste repurposing and waste management: reduction of the amount of waste rejected in natural environment (reuse as fuel).

- Mitigation of air pollution: reduction of more than 80% of combustion smoke.

Economic benefits

- Strengthening economic competitiveness of industries: reduction of energetic charges with the decline in purchases of timber and improving of the energy efficiency of transformation process.

- Commercial valuation of biochar: production of a new renewable fuel, pyrolysis by-products, that can be valued in other markets.

Consideration of local specificities

- Local resources taken into account for the production, replication and maintenance of equipment: skill transfer through trainings for young technicians and artisans; strengthening of manufacturers in order to allow replication of the technology in the long run.

Agrovalor actions

Agrovalor documents

Progress report from January to June 2025 - ACAMOZ 2 (portuguese)

Annual Report - 2024